SUNSTARS POULTRY PRODUCTS Sunstars Poultry Products is a leading poultry industry in Pollachi, 8/3 ASD PURAM, Mahalingapuram, Pollachi, Coimbatore, Tamil Nadu, 642002

SUNSTARS POULTRY PRODUCTS

Sunstars Poultry Products is a leading poultry industry in Pollachi,

8/3 ASD PURAM, Mahalingapuram, Pollachi, Coimbatore, Tamil Nadu, 642002

Phone : 04259 - 233658 / 59

Mobile : +91 - 98654 - 05999

sunstarspoultryproducts@yahoo.com

info@sunstarspoultry.com

WELCOME TO SUNSTAR POULTRY PRODUCTS

Sunstars Poultry Products is a leading poultry industry in Pollachi, Tamilnadu India. Our main products are Broiler Chicks, Chicken and Hatching Eggs, feeding. Our broiler age is below 5 weeks and its body weight is 1.9 - 2.1 kg with tender, soft, pliable smooth textured and flexible breast Meat.

Government has introduced number of additives for efficient and economic broiler productions. We use those vaccination in our poultry to make broiler free from diseases.

OUR SERVICES

Sunstars Poultry Products offer three types of vaccination, this can be Marketed single, double or Triple vaccination. They are equipped with adjustable width dual syringes, which have been designed to guarantee the best possible results, less stress to the bird, increased accuracy and reduced operator fatigue. At the slightest touch of a button the bird is inoculated.

ABOUT US

Sunstars Poultry is an organization formed by Mr. K.P.Dhandapaani in the year 1995. Prior to this, Mr. K.P.Dhandapaani has worked in similar industry and gained knowledge. With the knowledge and experience in Indian poultry field, he started this organization with a vision to achieve many milestones in poultry industry. During 1995 and 1996, breeding farms started with Deep litter. With slow and steady rate, the company was able to produce 2000 batches. Simultaneously Egg sales also become part his business.

In 1999, Cage shed was incorporated for birds growth and was able to produce 300 batches. Feed Mill was started in the same year and was able to produce 4 tons per hour. Hatching also started with 6 setter machine and 3 hatching machine. And 6 more setter machines have been installed during the year 2001.

With new techniques and getting advanced in poultry field, the company was able to produce 5000 batches in the year 2003, 7500 batches in the year 2005, 10000 batches in the year 2008 and around 12000 batches in the year 2011. With more enquiries and to ease the process, Sunstars Poultry has got into Commercial Integration and now seeing phenomenal growth. After commercial Integration took place, weekly, we were able to produce 2000 batches and currently producing 100000 chicks per week. Our current major sales are happening in Tamil Nadu and Kerala. Our near future plan is to set up National Integration where Sunstars brand name will play an important role.And we got brand registration in the name of "SUNSTARS™ " in the year of 2011.

OUR PRODUCTS

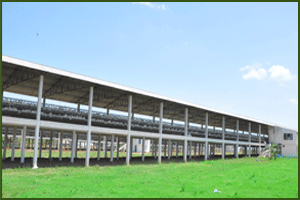

BREEDING FARMS

Sunstars Poultry Products has been maintaining a Broiler breeding farm in pollachi at an estimated cost of 5 lakhs. The envisaged capacity of the Farm is to near 30,000 parents and hatching 56 Lakhs eggs per annum. Presently we are producing and distributing about 1,00,000 chicks per week. Parental stock of broiler consists of a female line and male lines are selected at their eight weeks of age. Those which weigh the most in each breed are the ones chosen for breeding purposes.

The female lines from birds of White Rock background and the male lines are from the birds of Cornish ancestry. Hybrid vigour in next generation is obtained by systematic mating that may involve the crossing of different birds as stated, may be among different strains of same bird or in breed lines. The end product of all well planned selected crosses should be to produce a chick which will be white in color, yellow sanked, grows faster than either of the parents with tender meat and flexible breast cartilage.

HATCHERIES

Sunstars Poultry products hatcheries produce a majority of the broiler consumed in the developed world. It is a multibillion dollar industry, with highly regimented production systems used to maximize bird size versus feed consumed. Birds are produced and maintained under high density, which makes production and harvesting more economical.

Poultry generally start with naturally (chickens) inseminated hens that lay eggs, the eggs are cleaned and shells are checked for soundness before putting them in the incubators. The incubators control temperature and humidity, and turn the eggs until they hatch.

Generally large numbers are produced at one time so the resulting birds are uniform in size and can be harvested at the same time. Once the eggs hatch and the chicks are a day, they are often vaccinated, beak-trimmed and or toe-clipped, this involves the removal of half of the top beak and the clipping of the toe ends.After these procedures, they are moved to enclosed buildings to be raised until harvest. For chickens bred as (egg) layers, only the female chicks are considered to be of value.

FEED MILL

Sunstars Poultry Products has maintaining feed mill for broiler. Cost of feeding in case of broiler is around 70 percent of total expenditure and basically two types of ration is feed to the birds. Broiler starter ration characterized by high crude protein(22 percent) and less metabolizable energy, whereas, the finisher ration consists of less CP and more metabolizable energy.

Feed consumption under normal condition is around 100g/d/bird, though it varies from 50-120g/d depending upon various environmental and management system.

Maize, soya DCP, Sterlized Fish, shell git, Dry fish, RB-oil, etc and other unconventional feed ingredients may be incorporated. However, barley is not incorporated in higher quantity due to presence of endoglucan contentand birds are deficient of endogluconase enzyme.So during the formulation of the ration of the broiler, priority should be given to on anti nutritional and toxic factors in the feed ingredients and maximum limit of incorporation in the ration. BIS specification for requirement of broiler which should be in mind for computation of ration.

BROILER

Sunstars Poultry Products is concentrating mainly on Broiler productions. Broiler may be derfined as the young chicken of either sex, below 8 weeks of age, weighing 1.4-2.0 kg body weight with tender, soft, pliable smooth textured meat and flexible breast. Broiler are very sophisticated and subtle enterprise which is very economical when reared with great care in terms of nutrition and disease management. In India presently, high quality chicks, equipment, vaccines and medicines are available. Technically and professionally competent guidance is also available to the farmers.

The management pratices have improved and disease and mortally incidents are much reduced. Broilers farming has several advantages like low initial investment and faster return of investment . The rearing peroid is 6 to 7 weeks only and more number of flocks can be taken in the same shed. Due to its high feed conversion efficiency minimum amount of feed is required for unit body weight. Our Broiler division are located at Pollachi (Administrative/ Branch Office), Perundurai and Tindivanam is under processing

OUR PRODUCTS

- BREEDING FARMS

- HATCHERIES

- FEED MILL

- BROILERS